- 1. Introduction to CNC Machining

- 2. Fundamental Concepts of CNC Axis Systems

- 3. Breakdown of Axis Categories

- 4. Technical Differentiation Factors

- 5. Industrial Applications

- 6. Advantages & Limitations

- 7. Cost Factors

- 8. Future Trends in Multi-Axis Machining

- 9. Conclusion

1. Introduction to CNC Machining

CNC machining is a core technology in modern manufacturing. It is a process that uses computer-controlled machines to create parts. The term CNC stands for Computer Numerical Control. This method makes a machine follow pre-programmed instructions. CNC machining is used to make parts from many different materials. These include metals, plastics, and composites.

The axis configuration is a key part of any CNC machine. The number of axes a machine has affects several things. It determines the complexity of the parts it can make. It also influences production efficiency and the final surface quality. The axis count is a major factor in the final cost.

Choosing the right number of axes is important. For simple parts, a 3-axis machine is often enough. For complex parts, more axes are needed. This choice matters a lot for both creating a single prototype and for making parts in high volumes. For example, a company making an aerospace part will need different equipment than a company making a simple bracket. This is where precision CNC machining comes into play. It ensures the final product meets exact specifications.

The process of CNC machining is critical for a wide range of industries. This includes automotive, medical, and aerospace. CNC machining for aerospace parts requires the highest level of precision and reliability. Similarly, medical CNC machining demands strict tolerances. This is because medical devices must be safe and effective. Prototype CNC machining allows engineers to test new designs quickly and accurately. This is before they commit to large-scale production.

Understanding what CNC machining is and what it stands for is the first step. It is a powerful tool. It allows for high-precision manufacturing. The following sections will explain the fundamental concepts of CNC axis systems. They will also detail the differences between 3-axis, 4-axis, and 5-axis machines. This will help you understand how to choose the right machine for your project. This is whether you are looking for china cnc machining service or working with a precision CNC machining company locally.

2. Fundamental Concepts of CNC Axis Systems

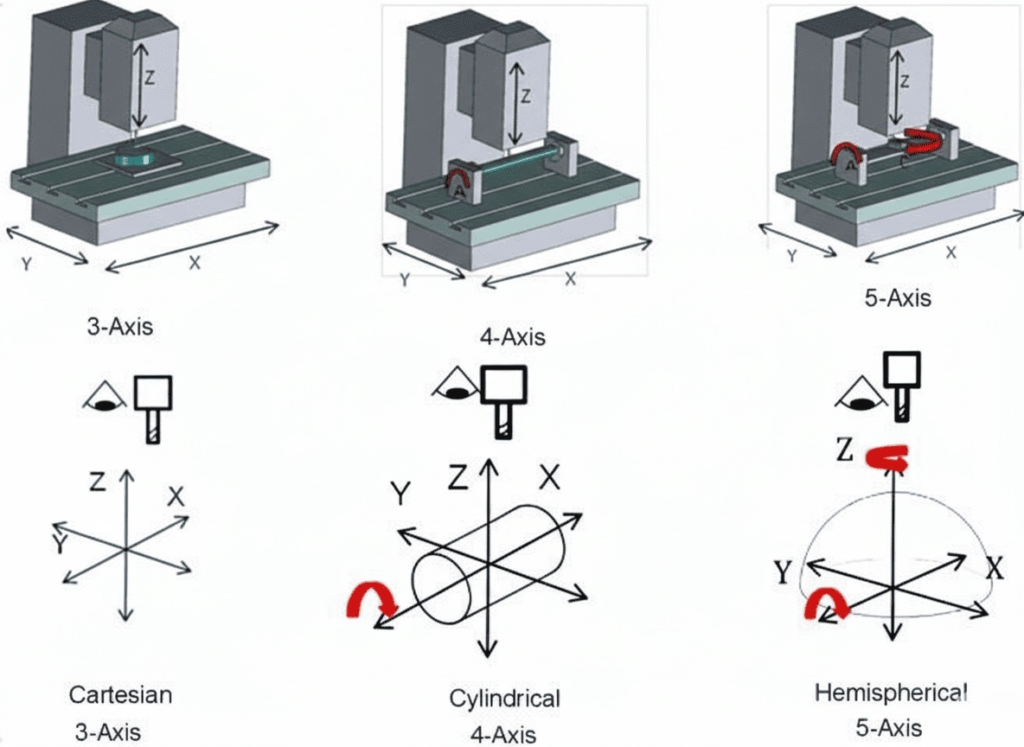

Understanding CNC axis systems is key to grasping how these machines operate. An axis is a path of movement on a CNC machine. There are two main types of axes. These are linear axes and rotational axes.

Linear axes are the most basic. They move along a straight line. These are the X, Y, and Z axes. The X-axis handles movement from side to side. The Y-axis controls movement from front to back. The Z-axis controls movement up and down. Most simple CNC machines have only these three axes.

Rotational axes move in a circular motion. They are named A, B, and C. The A-axis rotates around the X-axis. The B-axis rotates around the Y-axis. The C-axis rotates around the Z-axis. Adding these rotational axes increases a tool’s ability to reach complex surfaces. This concept is called kinematics. Kinematics explains how the extra axes give the tool more freedom to move.

CNC machines can have different configurations. Some machines move the workpiece (the table). Others move the spindle (the tool). For example, a machine may have a table that rotates. Another machine may have a spindle that tilts. Both designs achieve the same goal. They both add more axes of movement. These machines can also be open or closed. The open design gives a bigger work area. The closed design is better for safety and keeping chips contained.

This knowledge of axes and configurations is fundamental. It helps to understand the differences between 3-axis, 4-axis, and 5-axis machines. This is the foundation for a wide range of applications, from cnc prototype machining to cnc production machining. The choice of machine depends on the part’s shape and the required level of cnc precision machining.

3. Breakdown of Axis Categories

Understanding the specific capabilities of each type of machine is crucial. Here is a detailed breakdown of 3-axis, 4-axis, and 5-axis CNC machining.

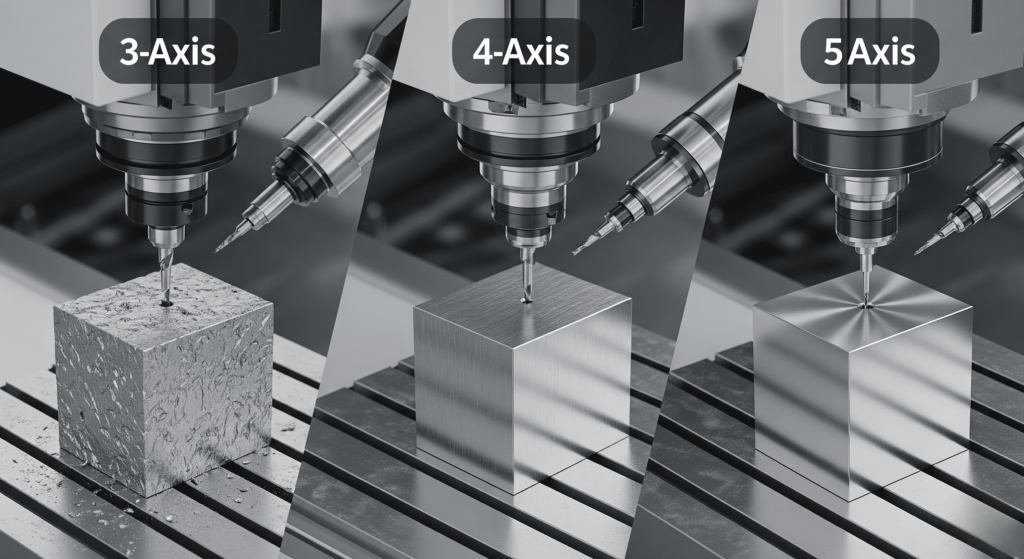

3.1 3-Axis Machining

3-axis machining is the most common type of CNC operation. The machine uses the X, Y, and Z axes. The tool moves up, down, left, right, forward, and backward. The workpiece remains in one fixed position.

Typical operations for 3-axis machines include drilling holes and milling flat surfaces. They are also used for creating 2.5D pockets and contouring simple shapes. Common applications for 3-axis machining include making simple sheet metal parts, housings, brackets, and enclosures. This type of machine is ideal for projects that do not require complex curves or undercuts. It is a cost-effective solution for many standard parts.

3.2 4-Axis Machining

A 4-axis machine adds one rotational axis to the standard three linear axes. This new axis is usually the A-axis (rotation around the X-axis) or the B-axis (rotation around the Y-axis). This extra axis allows the machine to machine a part from four different sides without re-fixture.

There are two main modes for 4-axis machining: indexing and continuous. In indexing mode, also known as 3+1, the machine first tilts the part to a set angle. Then, it machines the part with the three linear axes. In continuous mode, all four axes move at the same time. This allows for complex cuts. 4-axis machines are suitable for making parts with features on multiple faces. Examples include spiral grooves, cam lobes, gear housings, and radial arrays.

3.3 5-Axis Machining

5-axis machining uses two rotational axes in addition to the three linear axes. These are typically the A and B axes or the A and C axes. This allows the tool to approach the workpiece from almost any direction. This gives great flexibility.

Just like 4-axis, 5-axis machining has different modes. Positional 5-axis machining, or 3+2, involves tilting the tool to a fixed angle and then machining with the three linear axes. Simultaneous 5-axis machining is different. In this mode, all five axes move together at the same time. This is used for creating complex, organic surfaces.

5-axis machines are essential for making parts with complex geometries. Applications include aerospace blades, orthopedic implants, and turbine components. They are also used for creating injection mold cavities. This capability makes them a key component of modern aerospace CNC machining and medical CNC machining services.

4. Technical Differentiation Factors

When you compare 3-axis, 4-axis, and 5-axis machining, several technical factors stand out. These factors help you decide which machine is right for a specific job.

4.1 Machine Setup and Programming

The number of axes affects how a machine is set up. It also impacts the programming needed. CAM software is a must-have for all CNC machines. However, the software for multi-axis machines is more advanced. For 5-axis machines, you need high-end CAM software like Mastercam, HyperMill, or NX. These programs can create complex toolpaths. They also run simulations to prevent collisions. The fixture setup is also simpler for 5-axis machines. This is because a 5-axis machine can work on a part from many angles without the operator repositioning it. This reduces human error and saves time.

4.2 Cutting Strategies

Each machine type has its own cutting strategies. 3-axis machines use basic methods like climb milling and conventional milling. They are also good for adaptive clearing. 4-axis machines are good for rotary machining. They are also used for engraving on cylindrical parts. 5-axis machines use more advanced techniques. These include swarf cutting, contouring, and flowline machining. These methods allow for very smooth and complex surfaces.

4.3 Tool Accessibility and Reach

The number of axes directly impacts how the tool can reach a part. On a 3-axis machine, the tool can only move in straight lines. This can force the use of long tools to reach certain areas. Long tools can lead to tool deflection and chatter, which lowers accuracy. A 5-axis machine can tilt its tool or table. This means it can use shorter tools. Shorter tools are more rigid, which improves the surface finish and overall part quality.

4.4 Accuracy and Tolerances

More axes often mean higher precision. Here is a comparison of typical tolerances:

| Machine Type | Linear Tolerance | Rotational Tolerance |

|---|---|---|

| 3-Axis | ±0.001″ (0.0254 mm) | N/A |

| 4-Axis | ±0.001″ (0.0254 mm) | ±0.01° |

| 5-Axis | ±0.0005″ (0.0127 mm) | ±0.008° |

Several factors influence these numbers. These include machine calibration, backlash, and thermal stability. Precision CNC machining requires careful control of these elements.

4.5 Surface Finish

The number of axes also affects the surface finish.

- 3-axis machines often produce a surface finish of about 1.6 µm Ra. This is good for many standard applications.

- 4-axis machines can achieve a better finish, around 0.8 µm Ra.

- 5-axis machines can produce a very smooth finish, about 0.4 µm Ra. Some can even create a mirror finish.

This is a key consideration for parts that need a perfect surface. This is common in aerospace CNC machining and with medical implants.

4.6 Cycle Time and Productivity

Multi-axis machines can reduce overall cycle time. This is because they need fewer tool changes and fewer times the operator needs to reposition the part. Simultaneous 5-axis machining is the fastest method. However, it requires advanced programming and post-processing. This higher productivity helps balance the initial CNC machining cost.

4.7 Cost Analysis

The cost of a machine increases with the number of axes.

- A 5-axis machine can cost 3 to 5 times more than a 3-axis machine.

- The operating costs are also higher. This is because you need skilled operators and expensive software.

- The return on investment (ROI) is key. For low-volume, complex parts, a 5-axis machine can be worth the high cost. For high-volume, simple parts, a 3-axis machine is more economical. This is important for a precision CNC machining company to consider.

5. Industrial Applications

CNC machining is used in many industries. The choice of 3-axis, 4-axis, or 5-axis depends on the specific parts and needs of the industry.

5.1 Aerospace

The aerospace industry demands high precision and complex parts.

- 3-axis machines are used for simpler parts like brackets and housings.

- 4-axis machines are used for parts with rotational symmetry, like impellers and engine mounts.

- 5-axis machining is essential for making complex aerospace parts. This includes turbine blades and fuselage structures. CNC machining aerospace parts requires the highest level of accuracy.

5.2 Automotive

The automotive industry uses CNC for many different components.

- 3-axis machines are good for engine covers and housings.

- 4-axis machines create parts like camshafts and gear housings.

- 5-axis machines are used for making prototypes. They also create complex parts like intake manifolds and cylinder heads.

5.3 Medical

Medical CNC machining requires great precision for patient safety.

- 3-axis machines make surgical trays and other simple tools.

- 4-axis machines are used for dental implants and bone screws.

- 5-axis machines are used for complex parts like prosthetics, orthopedic implants, and surgical guides.

5.4 Electronics & Energy

- 3-axis machines are used for PCB housings and casings.

- 4-axis machines make parts like heat sinks and motor shafts.

- 5-axis machines are used for critical parts like turbine disks and compressor parts. They also create high-density connectors.

5.5 Mold & Die

CNC machining is crucial for creating molds.

- 3-axis machines are used for simple injection molds.

- 4-axis machines are good for angled cavities and engraved details.

- 5-axis machines are needed for complex freeform molds and high-polish optical molds.

6. Advantages & Limitations

Each type of CNC machine has specific pros and cons. Understanding these helps in making a good choice for your project.

6.1 3-Axis

3-axis machines have several clear benefits. They are simple to use. They are also very cost-effective. The programming for them is straightforward. 3-axis machining is perfect for simple geometries and flat parts. The main limitations are their inability to make complex parts with undercuts. The surface finish can also be rougher. Also, you may need more setups to finish a part. This is because the machine cannot reach all sides in one go.

6.2 4-Axis

A 4-axis machine offers a good balance between cost and complexity. It can make parts that are too complex for a 3-axis machine but do not need 5-axis capabilities. It is very good for machining cylindrical parts. This includes things like shafts and gears. However, it still has limits. It cannot create deep undercuts or complex organic shapes easily.

6.3 5-Axis

5-axis machining offers the highest level of flexibility, accuracy, and surface finish. It can create very complex parts in a single setup. This reduces the number of times you must reposition the part. This saves a lot of time. The main downside is the high cost. The machine itself is expensive. The required CAM software is also costly. You also need highly skilled operators to program and run the machine.

7. Cost Factors

The cost of CNC machining is not just about the machine itself. Many other things add to the final price.

7.1 Machine & Tooling Costs

The initial cost of the CNC machine is the biggest factor. 3-axis machines are the cheapest. A new 3-axis mill can cost from $20,000 to over $100,000. 4-axis machines are more expensive. They can range from $80,000 to over $250,000. A 5-axis machine can cost from $250,000 to over $1 million. The more axes a machine has, the more complex it is. This drives up its price. Tooling is another cost. 5-axis machines often need special, more expensive tools.

7.2 Programming & Software Costs

The software for each machine type has a different cost. 3-axis CAM software is the most basic. Its price is lower. CAM software for 4-axis and 5-axis machines is more advanced. It costs much more. You also need to pay for regular software updates.

7.3 Operator & Labor Costs

The skill level of the operator affects the labor cost. A 5-axis operator needs more training and experience. They get paid more than a 3-axis operator. A skilled operator is a key part of precision CNC machining. This cost adds up, especially for long production runs.

7.4 Material and Production Volume

The material used also changes the price. Aluminium CNC machining is cheaper than ceramic CNC machining. This is because ceramic is harder to machine. The amount of parts you make also matters. For high-volume production, a 3-axis machine can be cheaper per part. This is true even if the setup takes longer. For low-volume or prototype CNC machining, a 5-axis machine can be more cost-effective. This is because it reduces the need for multiple setups.

7.5 Cost-Benefit Analysis

Choosing the right machine is a balance. It is a choice between the upfront CNC machining price and the final cost per part. For many simple parts, a 3-axis machine is the best option. For complex cnc machining aerospace parts or medical devices, the higher cost of a 5-axis machine is justified. It provides better accuracy and a higher-quality finish.

8. Future Trends in Multi-Axis Machining

The world of CNC machining is always changing. New technologies are making machines smarter, faster, and more efficient. Here are some key trends shaping the future.

8.1 Hybrid Machining

Hybrid machining combines two different manufacturing methods. It joins CNC machining (subtractive manufacturing) with additive manufacturing (3D printing). A single machine can build up a part with 3D printing and then use CNC tools to finish it. This method is great for making complex parts. It also reduces material waste. This is because it only adds material where it is needed. Then, it subtracts to get the final shape.

8.2 Automation

Automation is a big part of the future. Robotic arms are now being used with CNC machines. Robots can load and unload parts from the machines. This lets the machine run 24/7 without a human operator. Automation increases productivity and reduces human error.

8.3 AI-Driven Toolpath Optimization

AI is changing how toolpaths are created. AI can analyze a part’s design and find the most efficient way to machine it. This includes the best tool, the best speed, and the best path. AI-driven toolpath optimization can reduce production time and improve the final quality of the part.

8.4 Digital Twin

A digital twin is a virtual copy of a physical machine. It lets engineers simulate the entire machining process on a computer before they cut any metal. This helps them spot problems. They can fix issues like collisions before they happen. This saves time and money. It also helps with maintenance. A digital twin can predict when a machine will need repair. This helps prevent unexpected downtime.

9. Conclusion

This article has explained what is cnc machining and the differences between 3-, 4-, and 5-axis machines. CNC machining stands for Computer Numerical Control. Each type of machine has its own pros and cons. The choice depends on the project’s complexity, required precision, and budget. For simple jobs, cnc machining china can provide a cost-effective solution with 3-axis machines. For high-end aerospace or medical parts, 5-axis machines are the standard.

Here at KAIYAN, we are a leading precision CNC machining company. We specialize in a wide range of services. We use the latest technology to meet your needs. We are experts in cnc precision machining parts. Whether you need cnc plastic machining, aluminium cnc machining, or ceramic cnc machining, our team is ready to help. We are experts at production cnc machining and prototype cnc machining. We ensure that your parts are made with the highest quality and precision.