In the realm of metalworking, two processes stand out for their versatility and efficiency: Metal Stamping and Milling. These techniques are pivotal in transforming raw metal into functional components, yet they cater to different manufacturing needs. Whether you’re seeking Metal Stamping Services or exploring milling options, choosing the right process can significantly affect your project’s timeline, budget, and quality. This article provides an in-depth comparison of Metal Stamping and Milling, focusing on time, cost, and quality, to help you make an informed decision for your next project.

What is Metal Stamping?

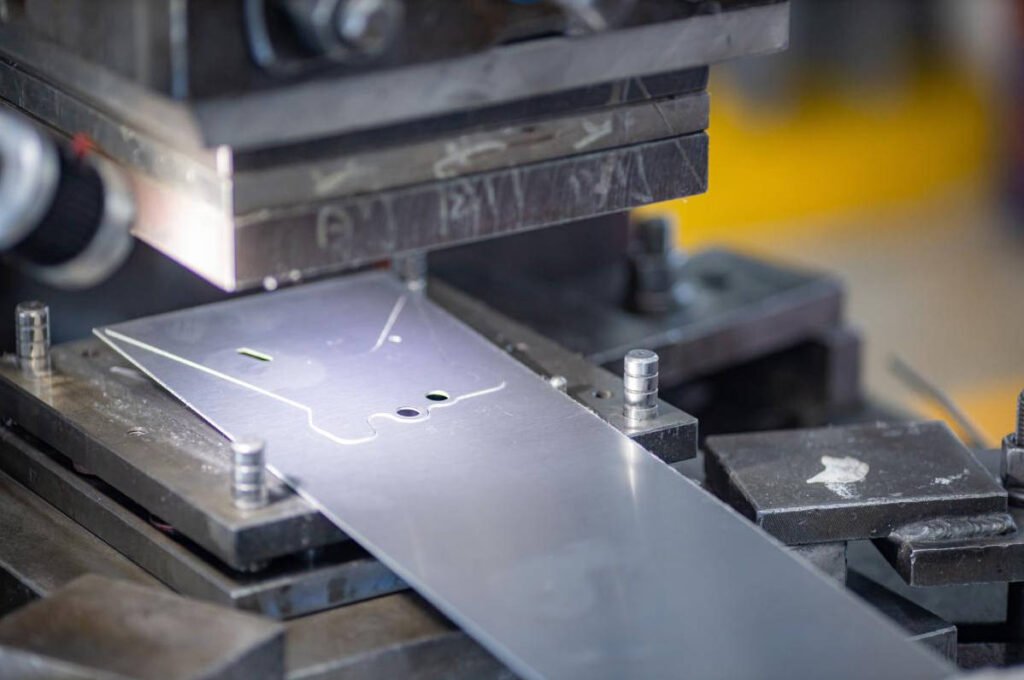

Metal Stamping is a manufacturing process that shapes flat metal sheets into specific forms using dies and presses. It’s a cornerstone of Sheet Metal Stamping, renowned for producing parts with consistent quality in high volumes. The process involves placing a metal sheet into a stamping press, where a die molds it through operations like punching, bending, or stretching.

Key types of Metal Stamping include:

- Progressive Stamping: The metal passes through multiple stations, each performing a distinct task, ideal for intricate parts.

- Deep Draw Stamping: Perfect for creating deep, hollow shapes such as cans or enclosures.

- Transfer Stamping: Suited for larger components, with the workpiece moved between stations.

Custom Metal Stamping allows for tailored designs to meet unique specifications, while Precision Metal Stamping ensures tight tolerances for applications requiring high accuracy, such as electronics or medical devices. Industries like automotive (e.g., brackets, panels), appliances, and electronics frequently rely on Stainless steel stamping services for durable, corrosion-resistant parts.

What is Milling?

Milling is a subtractive process that removes material from a workpiece using rotating cutters to achieve the desired shape. It’s highly adaptable, capable of producing complex geometries and prototypes with exceptional precision. Key milling variants include:

- CNC Milling: Automated and computer-controlled for repeatability and accuracy.

- Manual Milling: A traditional approach for simpler tasks or smaller workshops.

- Vertical and Horizontal Milling: Defined by spindle orientation, each suited to specific part designs.

Milling excels in crafting prototypes, custom components, and intricate parts for industries like aerospace, automotive, and machinery manufacturing.

Time Comparison

Time efficiency is a critical factor in manufacturing. Here’s how Metal Stamping and Milling stack up:

- Setup Time: Metal Stamping demands significant upfront time to design and fabricate the die, often taking weeks. Milling, particularly CNC milling, requires less setup time, involving only programming and workpiece preparation.

- Production Time: Once the die is ready, Metal Stamping produces parts rapidly—often in seconds—making it ideal for large runs. Milling, however, takes longer per part, as each piece is machined individually.

Metal Stamping is faster for high-volume production. For instance, producing 10,000 brackets via Sheet Metal Stamping can outpace milling significantly. Conversely, Milling is quicker for small batches or prototypes, avoiding the lengthy die-making phase. If you need a single custom part, Milling saves time upfront.

Cost Comparison

Cost considerations often drive process selection. Let’s break it down:

- Initial Setup Costs: Metal Stamping involves high initial expenses for die creation, ranging from thousands to tens of thousands of dollars. Milling has lower startup costs, requiring only raw material and machine setup.

- Per-Unit Costs: In Metal Stamping, the cost per part drops sharply with volume, making it economical for large-scale production. Milling maintains a consistent per-unit cost, regardless of quantity.

Metal Stamping saves money on large runs. For example, stamping 100,000 components might cost pennies per part, while milling the same volume would be far costlier. For small orders or custom jobs, Milling is more budget-friendly, as it sidesteps expensive tooling.

Quality Comparison

Quality hinges on precision, surface finish, and material integrity:

- Precision: Milling offers superior precision, especially for complex shapes, with tolerances as tight as ±0.001 inches. Precision Metal Stamping achieves good accuracy but may need secondary processes for the finest tolerances.

- Surface Finish: Milling delivers smooth finishes directly, while stamped parts might require additional polishing.

- Material Integrity: Stamping can work-harden materials, enhancing strength but potentially causing brittleness. Milling preserves the material’s original properties.

Milling excels in precision for intricate parts, making it ideal for aerospace or medical applications. For consistent quality across millions of units, such as automotive components, Metal Stamping Services shine. Below is a comparison table:

| Aspect | Metal Stamping | Milling |

| Precision | Good, may need finishing | Excellent, tight tolerances |

| Surface Finish | May require secondary processes | Smooth directly from process |

| Material Impact | Work-hardening possible | Preserves original properties |

When to Choose Metal Stamping

Opt for Metal Stamping when:

- You need high-volume production (thousands or millions of parts).

- Parts have simple to moderate geometries.

- Cost per unit is a priority.

- Consistency across large batches is essential.

Metal Stamping Services, including Stainless steel stamping services, are perfect for automotive, appliance, and electronics industries, where speed and uniformity are key.

When to Choose Milling

Choose Milling when:

- You’re prototyping or producing small batches.

- Parts feature complex, intricate designs.

- High precision is non-negotiable.

- Design flexibility is required.

Milling suits aerospace, custom machinery, and prototyping, where precision and adaptability outweigh volume.

Case Studies

Case 1: Automotive Bracket Production

- Requirement: 50,000 brackets for a car model.

- Process: Metal Stamping.

- Outcome: High die cost offset by low per-unit cost and rapid production, ensuring uniform quality.

Case 2: Custom Aerospace Gear

- Requirement: One gear with complex geometry.

- Process: CNC Milling.

- Outcome: Quick setup, high precision, and no tooling overhead, meeting exact specifications.

These examples underscore how project needs dictate the best process.

Conclusion

Metal Stamping and Milling each offer distinct advantages. Metal Stamping excels in high-volume production, delivering speed, cost savings, and consistency—ideal for Custom Metal Stamping and large-scale Sheet Metal Stamping projects. Milling shines in precision, flexibility, and small-batch scenarios, perfect for intricate or prototype parts.

When deciding, assess your production volume, part complexity, and budget. For mass production, Metal Stamping Services are the go-to choice. For custom or low-volume needs, Milling offers unmatched versatility. Understanding these factors ensures your project achieves optimal time, cost, and quality outcomes.

FAQs

What’s the minimum order for Metal Stamping?

It depends on the provider, but many Metal Stamping Services suggest 1,000+ units to justify die costs, though some accommodate smaller runs.

Is Milling viable for large-scale production?

Yes, but it’s rarely cost-effective due to higher per-unit costs compared to stamping.

How do I pick the best process?

Evaluate volume, complexity, and precision needs. High-volume, simple parts favor Precision Metal Stamping; complex, low-volume parts suit Milling.