Computer Numerical Control (CNC) machining has revolutionized the manufacturing world by offering unparalleled precision, consistency, and versatility. The material selection plays a crucial role in determining the efficiency, cost-effectiveness, and overall quality of CNC machined parts. Among the various materials available for CNC machining, aluminum stands out due to its unique combination of properties, such as lightness, strength, machinability, and corrosion resistance. In this article, we will explore why aluminum is the ideal material for CNC machining, its benefits, applications, and how the machining process works with aluminum, using real-world data and examples to support the claims.

Table of Contents

- Introduction: Why Aluminum Material for CNC Machining?

- What Makes Aluminum Ideal for CNC Machining?

- Aluminum Properties That Enhance CNC Machining

- The Benefits of Using Aluminum for CNC Machining

- Aluminum vs. Other Materials for CNC Machining

- The CNC Aluminum Machining Process: Key Steps

- Applications of Aluminum in CNC Machining

- Prototype CNC Machining with Aluminum

- Challenges in CNC Machining of Aluminum

- Real-World Data on CNC Aluminum Machining

- Conclusion: Why Aluminum Remains a Top Choice

Introduction: Why Aluminum Material for CNC Machining?

CNC machining is a highly precise manufacturing process that involves the use of computer-controlled machines to produce parts from a variety of materials. The material chosen for CNC machining directly impacts the performance, cost, and final quality of the parts. Among the many materials used in CNC machining, aluminum has become one of the most popular choices. Whether for aerospace components, automotive parts, or electronics housings, aluminum offers an outstanding balance of properties that make it highly versatile for CNC machining.

Aluminum’s excellent machinability, strength-to-weight ratio, and ability to be recycled make it an ideal material for producing high-performance components at competitive costs. This article will explore why aluminum is an optimal material for CNC machining and dive deep into the reasons why manufacturers prefer it for producing precision parts across various industries.

What Makes Aluminum Ideal for CNC Machining?

Aluminum has several inherent characteristics that make it especially suitable for CNC machining. These characteristics allow manufacturers to produce parts that meet stringent quality and dimensional requirements while also keeping costs low. Below are some of the key features that make aluminum ideal for CNC machining:

1. Lightweight

Aluminum is one of the lightest metals available, with a density of about 2.7 grams per cubic centimeter, compared to steel’s density of 7.85 grams per cubic centimeter. This low density makes aluminum an ideal choice for applications that require high strength but need to minimize weight. In industries like aerospace, automotive, and electronics, reducing weight is critical for improving efficiency, fuel consumption, and performance.

2. Excellent Machinability

Aluminum is highly machinable due to its softness compared to other metals like steel or titanium. This means that aluminum parts can be produced faster and with lower wear on the tools used in CNC machining. This characteristic is one of the primary reasons aluminum is favored for mass production, as it helps reduce labor costs and machine downtime.

3. Corrosion Resistance

One of aluminum’s most notable properties is its excellent resistance to corrosion. Aluminum forms a natural oxide layer when exposed to air, which protects the material from rust and deterioration. This makes aluminum a preferred material for applications in harsh environments, such as marine or outdoor equipment.

4. Thermal and Electrical Conductivity

Aluminum has high thermal and electrical conductivity, which is why it is often used in applications requiring efficient heat dissipation or electrical conductivity. In the electronics industry, aluminum is commonly used for heat sinks and other components that need to efficiently transfer heat away from sensitive electronics.

5. Cost-Effective

Aluminum is relatively inexpensive compared to other metals such as titanium and stainless steel. It also offers a high strength-to-weight ratio, making it an economical choice for applications that need to meet both performance and budget requirements. Additionally, aluminum’s machinability helps to lower production costs further.

Aluminum Properties That Enhance CNC Machining

The specific properties of aluminum that make it an excellent choice for CNC machining include:

| Property | Description | Benefit to CNC Machining |

|---|---|---|

| Low Density | Aluminum has a low density, making it light in weight. | Helps reduce shipping costs and makes components lighter while maintaining strength. |

| High Machinability | Aluminum can be easily cut, milled, and drilled. | Reduces machining time and costs, allowing for faster production. |

| Corrosion Resistance | Forms a natural oxide layer that protects against rust. | Ideal for use in marine, aerospace, and outdoor applications. |

| Thermal Conductivity | Excellent at dissipating heat. | Prevents overheating in electronic applications and improves thermal management. |

| Electrical Conductivity | Aluminum is a good conductor of electricity. | Used in electrical connectors, housings, and power systems. |

The Benefits of Using Aluminum for CNC Machining

Aluminum’s properties contribute to several significant benefits that improve the efficiency and cost-effectiveness of CNC machining:

1. Reduced Manufacturing Time and Cost

Since aluminum is easier to machine compared to materials like steel or titanium, manufacturers can produce parts faster, resulting in lower labor costs. The ability to machine aluminum quickly without excessive tool wear also reduces the need for frequent tool replacements, thus cutting down on production costs.

2. High Strength-to-Weight Ratio

Aluminum provides a strong yet lightweight material that can withstand significant stress without adding unnecessary weight. This characteristic is especially important in industries like aerospace and automotive, where weight reduction is critical to performance.

3. Versatility in Applications

Aluminum can be used in a wide variety of industries, from aerospace to electronics, thanks to its versatility. It can be easily alloyed with other materials to enhance specific properties, such as strength or corrosion resistance, depending on the requirements of the application.

4. Eco-Friendly

Aluminum is 100% recyclable without losing any of its properties. Recycling aluminum requires only about 5% of the energy used to extract it from raw ore, making it an environmentally friendly choice for manufacturers concerned with sustainability.

Aluminum vs. Other Materials for CNC Machining

Although aluminum is a popular choice for CNC machining, it’s essential to compare it to other materials to understand its unique advantages. Below, we compare aluminum to steel, titanium, and plastics to see where it excels:

| Material | Density (g/cm³) | Strength (MPa) | Machinability | Cost |

|---|---|---|---|---|

| Aluminum | 2.7 | 90-250 | High | Low |

| Steel | 7.85 | 250-1300 | Medium | Medium |

| Titanium | 4.43 | 350-1500 | Low | High |

| Plastics | 1.2-2.0 | 20-150 | Very High | Low |

As seen in the table, aluminum strikes an ideal balance between machinability, cost, and strength, especially when compared to titanium, which is more difficult to machine and much more expensive, or steel, which is heavier and more costly.

The CNC Aluminum Machining Process: Key Steps

The CNC aluminum machining process involves several steps that ensure the production of high-precision parts. The primary steps are as follows:

1. Material Selection

Choosing the right aluminum alloy is crucial in CNC machining. Aluminum alloys like 6061 and 7075 are popular choices for machining due to their strength, corrosion resistance, and ease of machining. Selecting the right alloy ensures that the part will perform optimally in its intended application.

2. CAD Design and Simulation

After selecting the material, a digital 3D model of the part is created using CAD (Computer-Aided Design) software. The CAD model is then converted into machine-readable instructions (G-code) that guide the CNC machine in cutting and shaping the aluminum part.

3. CNC Machining

The CNC machine follows the instructions from the G-code to precisely cut, mill, and drill the aluminum material into the desired shape. The machine uses specialized tools like end mills, drills, and lathes to create the part.

4. Finishing Processes

After the machining process, the part may undergo finishing processes like anodizing, powder coating, or polishing to improve surface appearance, add additional durability, and enhance corrosion resistance.

Applications of Aluminum in CNC Machining

Aluminum’s versatility allows it to be used in a wide variety of industries and applications. Below are some of the key industries where CNC machined aluminum parts are commonly used:

1. Aerospace

Aluminum is widely used in aerospace applications due to its lightweight nature and high strength. Components such as aircraft fuselage panels, wing supports, and engine components are often machined from aluminum alloys to reduce weight while maintaining structural integrity.

2. Automotive

In the automotive industry, aluminum is used for parts such as engine blocks, transmission housings, suspension components, and body panels. The material’s light weight helps improve fuel efficiency while maintaining the strength needed for safety and durability.

3. Electronics

Aluminum’s excellent thermal conductivity and electrical properties make it an ideal choice for electronics, such as heat sinks, connectors, and enclosures. These parts help dissipate heat and ensure the longevity of sensitive electronic components.

4. Medical Devices

In the medical field, aluminum is used for producing components such as surgical instruments, implants, and diagnostic equipment housing. Its biocompatibility, strength, and corrosion resistance make it ideal for use in medical applications.

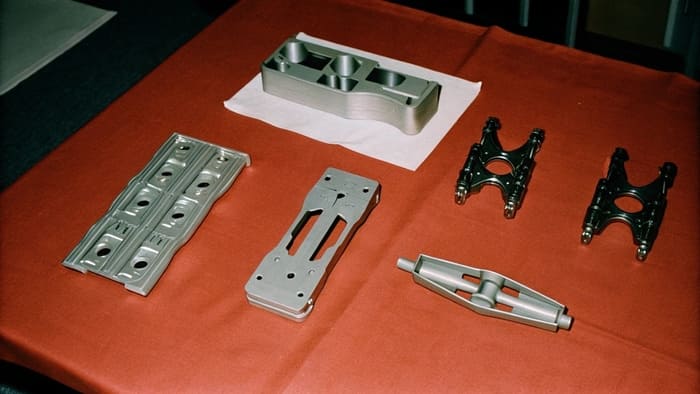

Prototype CNC Machining with Aluminum

Aluminum is commonly used in prototype CNC machining, where manufacturers need to create functional prototypes quickly and accurately. Aluminum prototypes allow engineers and designers to test designs before moving into full-scale production, saving time and money while ensuring that the final product will meet performance requirements.

Challenges in CNC Machining of Aluminum

Despite its numerous advantages, CNC machining of aluminum does come with some challenges. These include:

- Tool Wear: Aluminum’s soft nature can cause rapid tool wear, especially in high-volume production. Using high-quality cutting tools and maintaining regular tool changes can mitigate this issue.

- Chip Management: Aluminum generates long, stringy chips that can affect machining efficiency. Proper chip removal and tool design are essential for smooth machining operations.

- Heat Generation: Aluminum generates heat during machining, which can distort parts and degrade surface finishes. Effective coolant systems and heat management strategies are necessary to address this issue.

Real-World Data on CNC Aluminum Machining

Let’s take a look at some real-world data regarding CNC aluminum machining to highlight its performance across different industries:

| Industry | Common Parts | Machining Time per Part (min) | Cost per Part ($) |

|---|---|---|---|

| Aerospace | Fuselage Panels, Brackets | 60-90 | 500-1000 |

| Automotive | Engine Blocks, Transmission Housings | 30-50 | 300-600 |

| Electronics | Heat Sinks, Enclosures | 15-25 | 50-150 |

| Medical Devices | Surgical Instruments, Implants | 20-40 | 200-400 |

Conclusion: Why Aluminum Remains a Top Choice

Aluminum’s outstanding combination of strength, lightness, machinability, and cost-effectiveness makes it an optimal material for CNC machining. Its versatility across industries like aerospace, automotive, electronics, and medical devices further cements its status as a top choice for high-quality, precision parts. With continued advancements in CNC machining technologies, aluminum remains a material of choice for manufacturers aiming to meet tight tolerances, reduce costs, and achieve high performance.

Whether you’re looking to create prototype parts or scale up for mass production, CNC aluminum machining is a reliable, efficient process that continues to drive innovation across many industries.